PRODUCT 製品・サービス

FILTER CAGES リテーナ

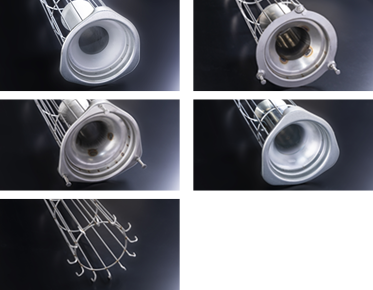

FILTER CAGES

(Industrial dust collector fabric filter parts)

リテーナ

Filter cages are used in "fabric filter dust collectors". They are metal fittings that support the "filter cloth" to filter dust generated in manufacturing and treatment processes in various fields such as mining, steel, cement, chemicals, and waste treatment, as well as soot and dioxin generated during incineration, to maintain the dust collection effect.

As a filter cage manufacturer trusted by our customers, we are particular about the materials, venturi tube, bottom plate, and other parts, and pursue high quality and low cost with our own production line using multi-spot automatic welding machines, and continue to challenge manufacturing with even more originality and ingenuity.

Features of Namita's Filter Cages 並田のリテーナの特長

Namita type upper hardware and bottom plate FEATURE

It can be used for a wide range of applications, regardless of how the filter cloth is installed (with or without a collar).

The entire circumference of the flange is folded back to greatly increase strength and prevent damage such as bending during installation and replacement work. A notch in the folded part allows the user to check the installation status of the filter cloth.

The retainer can be easily raised and lowered without a handle, improving workability during inspection.

The two-stage drawing of the cylindrical part improves the fit with the filter cloth and is effective in preventing the cloth from falling off.

The bottom plate of the filter cage is not welded, but fitted, eliminating damage to the filter cloth caused by welded bottom plates, such as weld marks and burrs on the edges of the bottom plate.

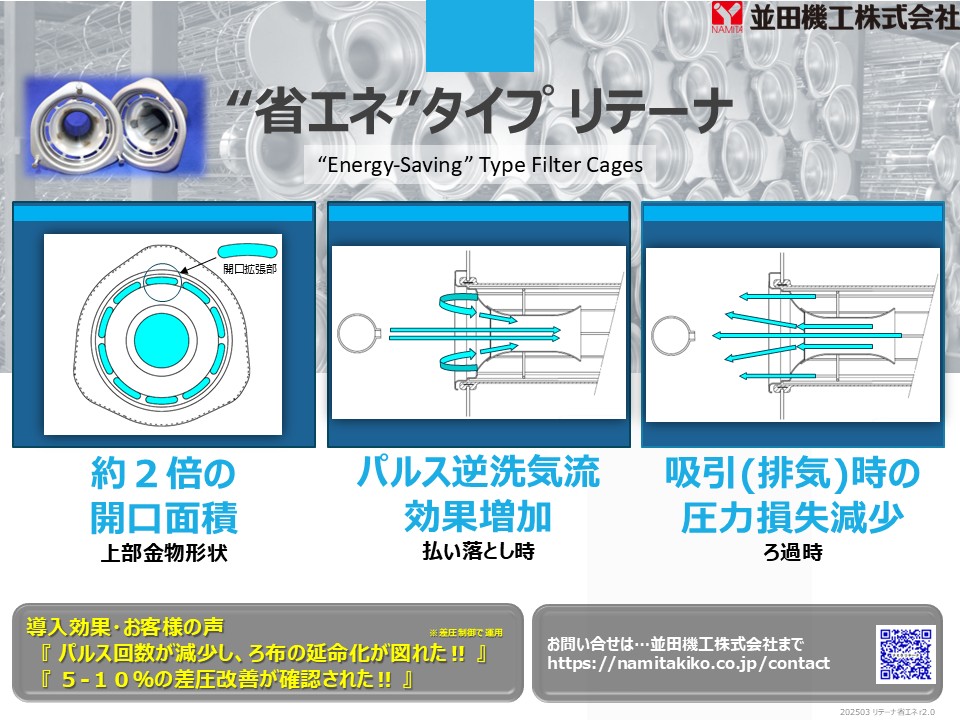

Reduction of pressure loss and flushing away effect FEATURE

By providing a bypass hole on the outside of the venturi pipe, we have developed an upper metal fitting that increases the suction area to reduce pressure loss and increase the effectiveness of pulse backwash airflow.

(Contact us for more information on “energy-saving” type filter cages.)

NSSC180 Filter Cages - High resistance to stress corrosion cracking

Are you having trouble? For poor environmental dust collectors…

Coke ovens, DAPS, CDQ, electric furnaces for steelmaking, biomass power plants, etc.

“Hard to crack… hard to break…”, “Low thermal expansion”, “High stress corrosion cracking resistance”

Ferritic Stainless Steel “NSSC180 Filter Cages

*NSSC180″ is a registered trademark of Nippon Steel Corporation.

Namita type filter cages POINT

-

POINT 01 Effect of two-stage aperture

The two-stage aperture of the upper metal part improves the fit with the filter cloth and is effective in preventing the cloth from falling off.

It can be used with or without a collar. -

POINT 02 The effect of folding back

The entire perimeter of the flange of the upper hardware is folded back to greatly increase strength and reduce bending and other damage during on-site work such as installation and replacement.

-

POINT 03 Effect of the notch

A notch in the folded part allows you to check the installation status of the filter cloth.

The filter cage can be easily raised and lowered without a handle, improving workability during inspection. -

POINT 04 What is an energy-saving venturi tube?

An upper metal fitting has been developed on the outside of the venturi pipe with a bypass hole to reduce pressure drop and increase the effectiveness of pulsed backwash airflow.

-

POINT 05 Various upper hardware

We have a wide range of hardware that matches various dust collectors to meet our customers' needs.

Custom-made products are also available, so please consult us.